Thermal-Structural Optimization Through Advanced Additive Manufacturing and Functionally Graded Material Solutions

Transform your thermal management challenges into competitive advantages with our cutting-edge functionally graded materials and additive manufacturing expertise.

The Challenge

Traditional thermal management systems struggle with extreme temperature gradients, leading to thermal stress, material failure, and compromised performance in critical applications.

Our Solution

Functionally graded materials engineered through advanced additive manufacturing create seamless thermal transitions, eliminating stress concentrations while optimizing heat dissipation.

The Impact

40%

Reduction in Thermal Stress

3x

Extended component lifespan

Industries We Serve

Delivering specialized thermal-structural solutions across mission-critical sectors

Aerospace & Defense

Challenge

Extreme thermal cycling in hypersonic flight environments

Solution

FGM heat shields with optimized thermal gradients

Results

60% weight reduction, 45% improved thermal performance

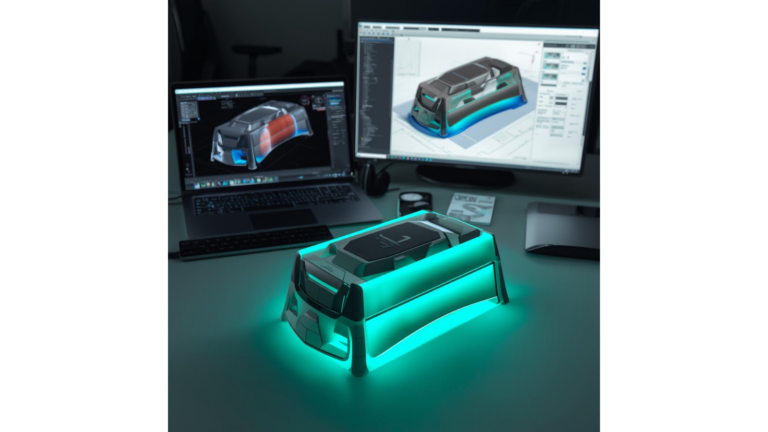

Automotive

Challenge

Battery thermal management in high-performance EV’s

Solution

Graded cooling plates with optimized conductivity profiles

Results

30% faster charging, 25 ºC temperature reduction

Thermal Systems

Challenge

High-flux cooling in power electronics and data centers

Solution

FGM Heat exchangers with topology optimized structures

Results

2x heat transfer efficiency, 25% volume reduction

Our Process

A proven three-phase approach to thermal-structural optimization

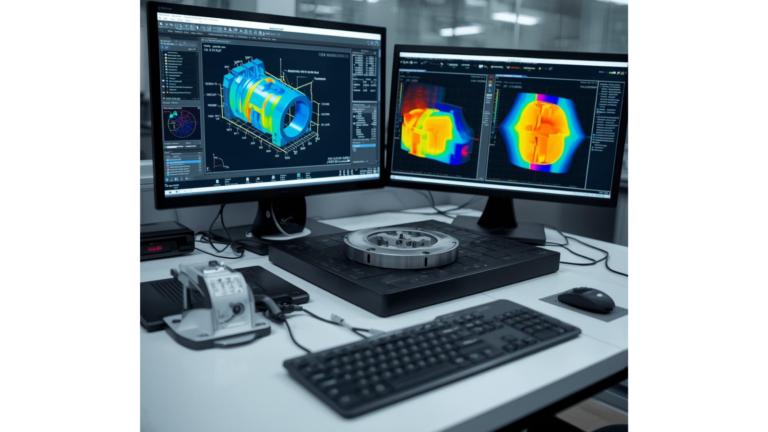

Discovery & Analysis

Comprehensive thermal-structural assessment using advanced simulation and material characterization. We analyze your current system's performance, identify optimization opportunities, and establish baseline metrics.

Timeline

2-3 weeks

Investment

€15K – 25K

Thermal mapping and stress analysis

Material selection and feasibility study

Preliminary optimization recommendations

Design & Optimization

Development of optimized FGM designs using multi-physics simulation and topology optimization. We iterate through design variations to maximize performance while meeting manufacturing constraints.

Timeline

4-6 weeks

Investment

€35K – 60K

Multi-objective optimization models

FGM composition gradient design

Manufacturing process qualification

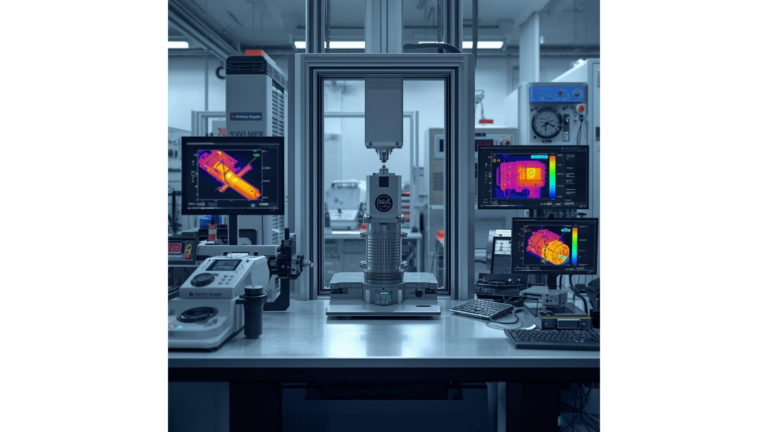

Validation & Implementation

Prototype fabrication, testing, and validation against design specifications. We work with your manufacturing partners to ensure seamless production integration and full documentation delivery.

Timeline

6-10 weeks

Investment

€50K – 100K

Prototype fabrication and testing

Performance validation and reporting

Production support and documentation

Ready to Optimize your Thermal Systems?

Start with a complimentary thermal assessment

Our team will analyze your current system and identify optimization opportunities. No cost, no obligation – just actionable insights from materials engineering experts.